3 July, 2023

Newsletter June 2023

Midsummer night is already over and summer is in full swing. We enjoy warm hours by the sea, in the forest, on the terrace or balcony. The world seems to turn a little slower.

However, this does not apply to the economy and business. Money does not sleep. Neither does the competition. The major German automaker Volkswagen just had to learn that painfully. Business in China is weakening - especially when it comes to e-mobility. After decades of market leadership, VW is no longer number 1 in China. The Chinese supplier BYD now dominates the world's largest car market. The pressure is mounting. With its Dolphin model, BYD is launching an e-car on the European market that clearly emulates VW's ID series but is considerably cheaper: 29,990 euros.

As if that were not enough, VW feels compelled to have its controversial plant in the Chinese province of Xinjiang examined by independent auditors. There are complaints about the human rights situation there, and it is Volkswagen's job to address these concerns, said Group CEO Oliver Blume. Human rights activists criticize VW for doing too little to combat forced labor in the supply chain.

So a lot of stress in China. And yet the huge country with its greedy market remains the most important trading partner not only for VW but for almost all European carmakers and industries. China has blackmail potential in many areas that make up a modern economy. Decoupling, separation, or diversification will not happen overnight. But in the medium term, Europe needs more independence not only from China but also from other countries with poor reputations. That's Euorbattery Minerals' core competence - in the field of battery minerals. I am not telling you anything new but still, it must be repeated again and again until everybody understands it. Especially those who have to make landmark decisions.

Trilateral powers united to reduce Europe's dependence.

The message seems to be heard. In a press conference last week, the economy ministers of Germany, France, and Italy announced increased cooperation regarding critical raw materials. The goal is to strengthen a secure and sustainable supply of raw materials for the European industry. Robert Habeck, the German Minister of Economics, summarized three pillars for the realization of this goal:

- The strengthening of the circular economy through a recycling industry,

- the alignment or cooperation of funding instruments and

- creating a platform knowledge for industries to increase the demand for "European" raw materials.

In addition to the general framework conditions, the acceleration of approval procedures had been discussed. Indeed, the starting points are very different - France and Italy, for example, provide financial support for mining and recycling projects, while Germany does not provide analogous funds. Anyway: both Germany and France are among the largest suppliers of electric cars in Europe. This cooperation emphasizes the urgency of further political and strategic development regarding the supply of raw materials.

Roberto at Bloomberg

Last week I had a brilliant background talk with Bloomberg’s Petra Sorge and Christoph Rauwald at the agency’s Berlin office. In fact, we were on the same page on many issues. Germany has been Europe’s economic engine for decades, pulling the region through one crisis after another. But that resilience is breaking down, and it spells danger for the whole continent.

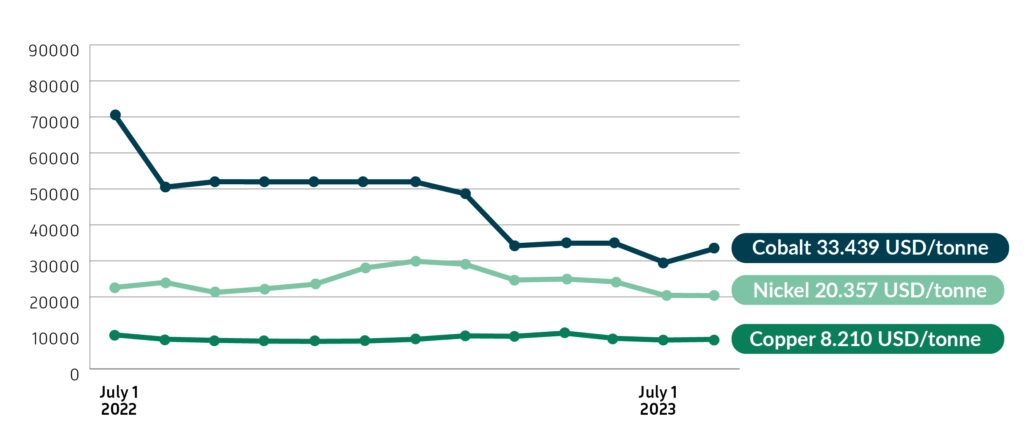

Decades of flawed energy policy, the demise of combustion-engine cars, and a sluggish transition to new technologies are converging to pose the most fundamental threat to the nation’s prosperity since reunification. Of course, this has an impact on the whole of Europe. What is needed to ensure that we don't lose touch, at least in terms of raw materials? Bloomberg and I largely agreed on this: Quite a lot! First: A social rethink is needed: Modern mining can be sustainable. Second: Mining must be included in the taxonomy, i.e. classified as sustainable in the EU's Critical Raw Material Act. We need safety guarantees, start-up financing, tax benefits and reliable energy supplies, faster approval processes, and price stability. Brussels: Please take over!

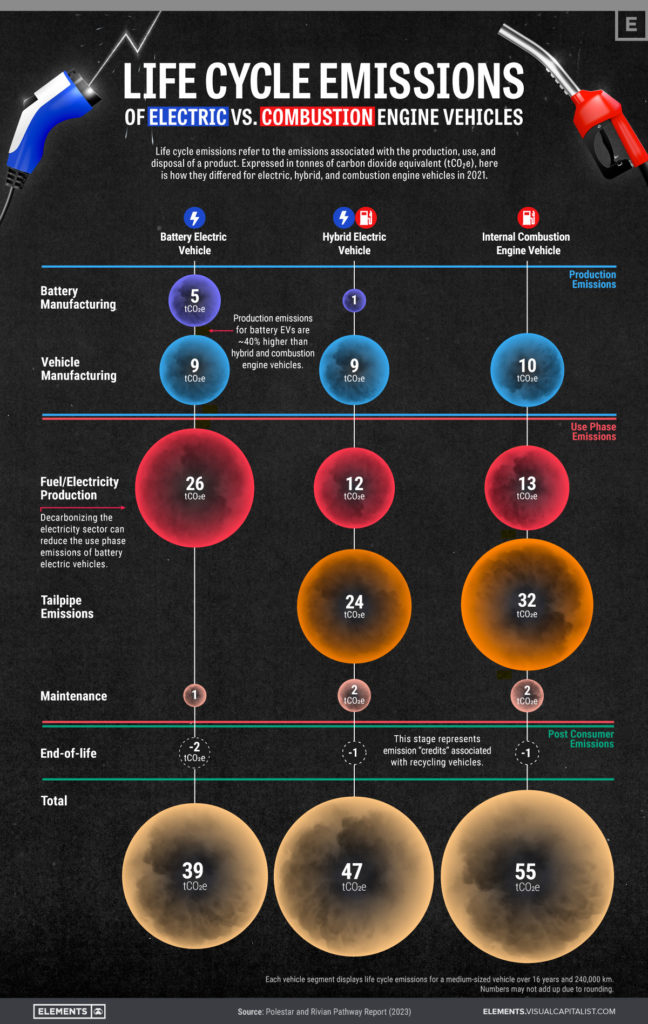

A few weeks ago, MEPs in Strasbourg voted by a large majority in favor of the new Battery Regulation. With this, the EU is adopting a new law that is intended to set new ecological and social standards in the manufacture of batteries. In the future, manufacturers of car batteries will therefore have to be able to demonstrate compliance with due diligence requirements along the entire supply chain. This begins - as one would expect - with the exploration of minerals and critical raw materials. Only recently, numerous initiatives drew attention to the problems in Congolese mines as part of the International Day Against Child Labor. For example, every battery should receive a battery passport that provides information about production and processing. In addition, labels or QR codes attached to the batteries are meant to provide information about the ecological footprint. Last but not least, the requirements for recycling are set out in the Battery Regulation. Accordingly, batteries for laptops or smartphones, for example, may no longer be glued or permanently mounted in the future. Quotas for taking back batteries (100 percent in the case of e-car manufacturers) are intended to save batteries from landfill and lead them back into the circular economy. By 2050, Europe aims to be a climate-neutral economy, the first continent in the world to do so. Batteries can help us move into this new era.

Source: Elements

An important component in batteries is rare earth elements (REEs). We reported on this critical raw material in a previous newsletter. The challenge: The extraction of REEs is very complicated because they are unevenly distributed in the earth's crust and the development of new deposits is often costly due to geological and geographical conditions. I am therefore pleased that further research has found our new method for 100% recovery of rare earth to be viable and realistic. The method enables rare earth to be recovered by using chemical substances at low temperatures, thus avoiding costly and time-consuming mechanical processing. This new method of very effective extraction enables the exploration of European mineral deposits, such as our project at Fetsjön.

Good news from Finland

I am very pleased with the progress of work on our Finnish battery mineral mine project. We received the official entry in the Finnish mining rights register. This is an important step in our preparations for commissioning the mine.

Jarkko Karvonen, Urban Planning Director Outokumpu town, and Ilari Kinnunen, Managing Director FinnCobalt, during the signing event.

In addition, the Outokumpu town Urban Development Board initiated the zoning and site plan change for the Hautalampi mine project. It is encouraging to see how our team in Finland works in close cooperation with the local authorities to move the project forward. Support from local stakeholders is at least as important as political tailwinds at the EU level.

I wish you all a relaxing and sunny summertime. The next newsletter will float into your inbox at the beginning of September.

Svenska

Svenska

Deutsch

Deutsch