4 December, 2023

Newsletter November 2023

Less than three weeks to Christmas. And in less than four weeks, 2023 will be over. It has been another exciting year. In January I wrote in our newsletter: “2023 is crucial for us and brings new opportunities, and I am excited to see what is in there for our mining company.” Well, many decisions have been made at our company Eurobattery Minerals, and the European level in Brussels. I would like to draw your attention to some major achievements this year:

- Eurobattery's Board of Directors has decided to issue 2,855,856 shares. With the resulting capital, we intend to acquire an additional 30 percent of the shares in FinnCobalt Oy to own 70 percent of this very promising Hautalampi project in Finland.

- The first phase of the environmental permitting process for the Hautalampi mine project has been completed. The environmental impact assessment has been fully approved by the Finnish authorities.

- The Finnish Safety and Chemicals Agency (Tukes) has registered the Hautalampi mining right in the Mining Register under the Mining Act. The Hautalampi mining area thus has full legal force for its underground mine and licence. Its licence has full legal force.

- FinnCobalt Oy has finalised the pre-feasibility study for its Finnish Hautalampi mining project.

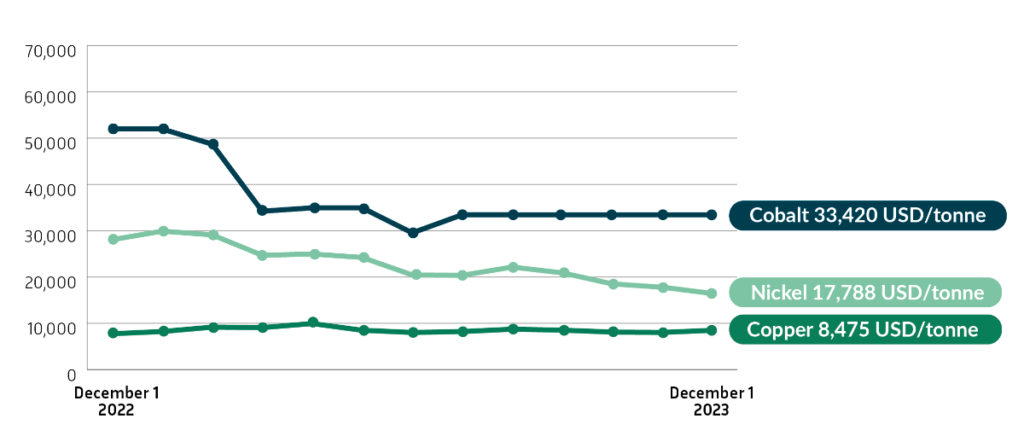

- The study, conducted by AFRY Finland, concludes that with a conservative metal price and a total capital expenditure of EUR 65.1 million (excluding unforeseen events), the amortisation period is 4.6 years. The total metal production over the expected 12 years of mining operations will be 11,400 tonnes of nickel and 2,900 tonnes of cobalt in the nickel-cobalt-cobalt concentrate and 9,600 tonnes of copper in the copper concentrate.

- Hautalampi's ore reserves and mineral resources have been categorised in the highest categories as viable mining projects according to the United Nations Framework Classification of Resources (UNFC).

- The company has expanded its partnership with the Smart Exploration Research Centre run by Uppsala University in Sweden.

- In the trialogue negotiations on the Critical Raw Materials Act (CRMA), the EU regulation for a secure and sustainable supply of raw materials, the Council, Parliament, and Commission reached a political agreement. Main points: The deadlines for faster authorisation procedures should not exceed 27 months for mining projects and 15 months for processing and recycling projects. The benchmarks of 10 percent for the extraction of domestic raw materials and 40 percent for processing in Europe were confirmed, while the benchmark for recycling was increased from 15 percent to at least 25 percent of the EU's annual raw material consumption.

You see, it HAS BEEN an exciting year. The direction remains clear, and the speed is increasing. The world markets dictate our actions. If Europe is too slow, it will lose the future. What many in the business world have long realised is also becoming increasingly urgent in politics. These are encouraging signs that make me optimistic about the new year 2024.

Visiting leftist German newspaper taz: Great interest in the CRMA

The other day I had an extraordinary talk with Heike Holdinghausen. She is an editor for economy and environment at Germany's best-known left-wing alternative newspaper taz, “die Tageszeitung”. It was a very good, in-depth discussion about the situation of mining in Europe in general and in Germany in particular. She was astonished to hear that there are currently very few new mining projects, even though politicians and industry agree that we need to promote and accelerate the extraction of critical minerals in Europe. The CRMA will soon force the authorities to tighten the timeframe for authorisation procedures and to make sure that Europe will achieve a higher degree of self-sufficiency when it comes to critical raw materials. But is this realistic? In Europe, where the word “mining” has a somewhat "dirty" and "environmentally destructive" connotation, do we have the technology and expertise to speed things up? I would say: definitely YES! But do we have a social consensus on this? On this, I’m afraid not. There is a lot of educational work to be done on modern, minimally invasive mining. The people at taz have understood this.

BMW in trouble

Maybe you have heard about this: A German investigative research team has unveiled that car giant BMW is sourcing "dirty" cobalt from Morocco. According to research, the state-owned Moroccan raw materials company Managem is leaking large quantities of toxic arsenic into the environment at its mine in Bou Azzer. Managem is obviously also failing to comply with international standards for the protection of workers.

In the meantime, BMW has commissioned two independent audits of the Bou Azzer mine. Maybe a bit too late? Like other car manufacturers, the Munich-based company is strictly monitoring its supply chains. BMW has gone even a step further with its decision to stop sourcing cobalt from the Congo, where it cannot be ruled out that children are also labouring in the mines. The approach of buying directly from the mines and not taking the diversions via the battery manufacturers is also the right one.

However, the car manufacturer now has to put up with the accusation that it has overdone it with its sustainability promises. Anyone who emphasises at every opportunity that they are particularly responsible and uses this as a selling point for their products really needs to be more on top of things. Journalists and scientists documented decades ago that this mine in Morocco is anything but a sustainability beacon. Clean sources of raw materials that are mined according to Western standards and in compliance with human rights and fair payment? BMW, take a close look at Eurobattery Minerals! Responsibly mined battery minerals – from Europe for Europe.

Svenska

Svenska

Deutsch

Deutsch